Certificate and System

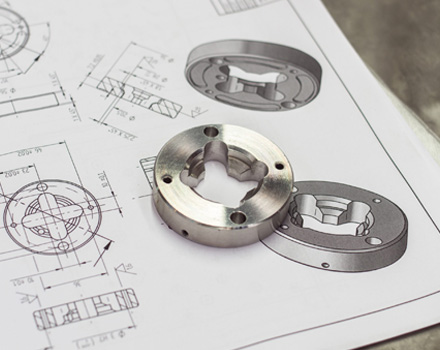

At Bhavi Brass Components LLP, we pride ourselves on our robust quality management system. Our dedication to excellence is reflected in our certifications and meticulous record-keeping practices.

ISO Certification 9001:2015 We are proud to hold ISO certification from TUV SUD, which underscores our commitment to maintaining the highest quality standards in the industry.

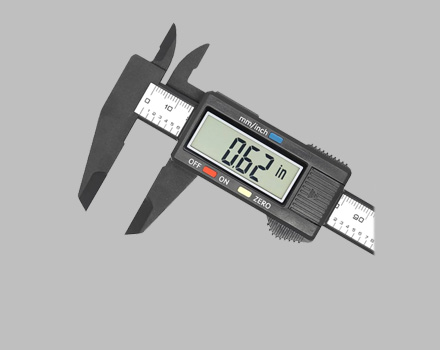

Up-to-Date Records of Quality Standards We maintain meticulous records of all quality standards and compliance measures. These up-to-date records ensure traceability and accountability at every stage of the production process, allowing us to meet and exceed industry standards.

ROHS Compliant Materials Our commitment to environmental sustainability is evident in our compliance with the Restriction of Hazardous Substances (ROHS) directive. All our materials are carefully selected and tested to ensure they meet ROHS compliance, contributing to a safer and healthier environment.